Views: 0 Author: Site Editor Publish Time: 2025-12-31 Origin: Site

Antiriot shields are vital protective equipment for law enforcement and security personnel, designed to withstand high-impact situations and ensure officer safety. Owning the right shield is only part of the equation—maintaining and storing it properly is crucial for long-term performance. Regular cleaning, inspection, and proper storage not only extend the shield’s lifespan but also guarantee that it performs reliably when it matters most. This guide provides practical tips and best practices for keeping your antiriot shields in top condition, helping teams stay prepared for any scenario.

Proper maintenance ensures your shields remain reliable and protective over time. Neglecting gear can lead to issues that compromise safety and performance, such as:

Cracks, scratches, or material weakening that reduce impact resistance

Loss of grip or control due to worn handles or slippery surfaces

Higher replacement costs from accelerated wear and tear

Safety hazards during critical operations when shields fail unexpectedly

Even simple actions—like wiping down your shield, checking for damage, and storing it correctly—can dramatically extend its service life. Maintenance isn’t optional; it’s an investment in safety and readiness. Teams that regularly care for their equipment avoid last-minute surprises and ensure every shield performs when it counts.

Regular inspections are like a “health check” for your gear. They help identify problems before they become serious and reduce the likelihood of equipment failure during high-risk situations.

Conduct a quick visual inspection before each use to catch obvious damage

Perform a more thorough check after each use, especially following heavy engagements or exposure to debris

Schedule monthly detailed inspections for shields in storage to monitor gradual wear

Quick, consistent checks save time and money. They also reinforce a safety-first mindset within your team.

| Component | Signs of Wear | Recommended Action |

|---|---|---|

| Shield surface | Scratches, cracks, discoloration | Repair minor damage, replace if deep cracks or structural flaws |

| Handles & straps | Loose fittings, fraying, worn | Tighten screws, re-stitch, or replace entirely |

| Mounting hardware | Rust, looseness, corrosion | Lubricate, secure, or replace parts |

| Identification markings | Fading, peeling, or unreadable | Re-label clearly or update inventory records |

A detailed record of inspections ensures each shield’s condition is traceable and can guide maintenance decisions. Record:

Inspection dates to track frequency and accountability

Damage or defects found, even minor scratches

Repairs or replacements performed

Cleaning schedules and any special care notes

Logs can be digital or printed. Using them consistently allows teams to anticipate replacement needs, track warranty claims, and maintain high operational readiness.

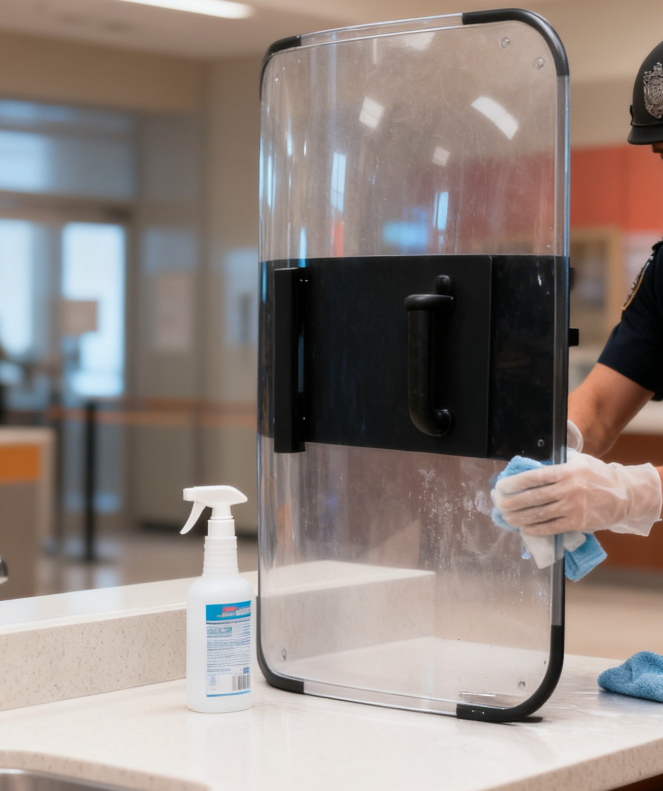

To clean your antiriot shield effectively, always use soft materials like cloths or sponges. Mild detergents mixed with water are ideal for removing dirt and grime without damaging the surface. Avoid abrasive cleaners or harsh chemical solvents, as they can scratch the polycarbonate, weaken the material, or harm handles and straps. Using the right materials preserves the shield’s protective properties and ensures it lasts longer.

Disassemble shields if possible (remove straps, handles, visors).

Wipe dirt, sweat, and fingerprints with cloth dampened in mild soap solution.

Rinse thoroughly to remove residue.

Air dry completely. Avoid heat or dryers—they can warp materials.

Certain components require extra attention. Fabric or padded straps should be washed gently and allowed to dry fully before reassembly, as moisture can encourage mildew and weaken fibers over time. For shields kept in storage, perform a full cleaning every three months, even if they haven’t been used. When removing stubborn debris, do it carefully to prevent scratches or other surface damage. Following these practices ensures your shield remains ready for action and maintains peak performance over time.

Antiriot shields perform best when stored in a controlled environment. Ideally, the temperature should remain between 15 and 25°C, and humidity should stay below 60%. Avoid storing shields in direct sunlight, damp areas, or outdoor sheds, as excessive heat, moisture, or UV exposure can degrade polycarbonate and other materials over time. Using climate-controlled rooms or adding a small dehumidifier can prevent mold, mildew, and warping, keeping your shields ready for action whenever they’re needed.

How you store your shields makes a big difference in their longevity. Flat stacking may seem convenient, but it can create pressure points that warp or damage the shield. Vertical storage preserves the shield’s shape and allows for easier access. Dedicated racks designed for shields are ideal. Label each slot with the shield’s ID or number to avoid confusion and streamline inventory management. Avoid cramming shields into tight corners, as this increases the risk of scratches, accidental falls, or deformation.

Handles, straps, and mounting hardware should be stored carefully, preferably separately from the shields themselves. Inspect each accessory during storage, checking for signs of wear, fraying, or loosening. Replace any damaged components before the shield is next deployed, ensuring that all parts are fully functional and secure. Organized accessories not only extend the life of the shield but also make preparation before duty faster and safer.

Helmet pads: Inspect for compression, tears, or loosening; replace to maintain head protection.

Straps and handles: Look for fraying, stretched elastic, or cracks; worn straps reduce grip and control.

Mounting hardware: Check screws, brackets, and fasteners for looseness or rust; replace to avoid failure during use.

Timing: Replace components immediately once wear is detected to ensure optimal shield performance.

Spare parts: Keep backup pads, straps, and handles to minimize downtime during maintenance.

Specialized equipment: Vehicles, water cannons, and transport units need routine care beyond shields.

Water systems: Flush water cannons after each use to prevent sediment or corrosion.

Hoses, nozzles, fittings: Inspect for leaks, blockages, and wear.

Mounting points: Ensure all brackets and fasteners are stable and secure.

Manufacturer support: Collaborate for technical guidance, replacement parts, and recall notifications.

Inspection skills: Teach how to spot cracks, scratches, or worn components early.

Cleaning and storage: Show proper methods for washing, drying, and vertical storage.

Component replacement: Explain when and how to replace pads, straps, or hardware.

Standard procedures: Establish clear SOPs to maintain consistency across teams.

Operational readiness: Empower personnel to care for equipment, improving safety and reliability in emergencies.

You should inspect your shield before and after every use, and perform a detailed monthly inspection if it is in storage.

Use a soft cloth or sponge with mild detergent and water, avoiding abrasive cleaners or harsh chemicals.

No, exposure to sunlight, heat, or moisture can degrade polycarbonate and other materials, reducing the shield’s effectiveness.

No, flat stacking can cause warping or pressure damage; vertical storage on dedicated racks is recommended.

Replace them if you notice fraying, cracks, looseness, or loss of elasticity to maintain grip and safety.

Proper maintenance and storage of antiriot shields are essential for safety, durability, and operational readiness. By following routine inspections, careful cleaning, organized storage, and timely component replacement, teams can maximize the effectiveness of their protective equipment.

For reliable antiriot shields and professional guidance on maintenance, Jiangsu Ultra Safe New Material Co., Ltd. offers high-quality solutions designed to keep law enforcement and security personnel safe and fully equipped for every challenge.